With the craft beverage industry continuing to boom, more and more people are stepping their foot into the business.  Canning lines within the craft beverage industry use a specific type of technology called counter pressure, or isobaric filling as some may say. Counter pressure technology for a long time was only available to crafters producing product on a large scale. However, in recent years and due to the uptake of small locally owned breweries, manufacturing companies have been able to scale down this technology and offer it to crafters of all production sizes.

Canning lines within the craft beverage industry use a specific type of technology called counter pressure, or isobaric filling as some may say. Counter pressure technology for a long time was only available to crafters producing product on a large scale. However, in recent years and due to the uptake of small locally owned breweries, manufacturing companies have been able to scale down this technology and offer it to crafters of all production sizes.

Because counter pressure canning gives the operator full control over the the atmosphere within the can, this is the preferred method industry wide. You may be wondering, what is counter pressure specifically and how is it used in a canning line? This technology involves a series of a several different valves and pressurization that allow for maximum output without the risk of oxygen absorption.

Benefits to Counter Pressure

- Little to no foam due to the equalized pressure within the tank.

- Maintained carbonation levels and no loss of CO2 to ensure the drink tastes the way it is suppose to.

- Prevention of oxygen absorption.

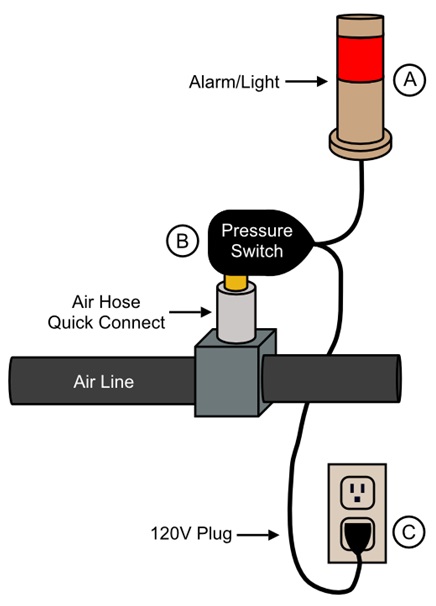

Having a reliable and effective CO2 canning line is a major component to running an efficient business. In order to effectively run, being able to monitor pressure loss in CO2 instantly can make a big difference to your bottom line. With Presairs’ Adjustable Pressure Monitor, you’ll never have a line down again.

Welcome to the perfect product for pressure monitoring solutions! Designed for monitoring industrial line pressure to notify personnel as soon as loss of line pressure begins to occur or an increase of pressure. These simple pressure monitoring solutions feature a flashing light (optional audible alarm) that’s designed to grab the attention anytime pressure is rising too high or falling too low in a system. Preventing & fixing issues before they cause significant downtime!

Welcome to the perfect product for pressure monitoring solutions! Designed for monitoring industrial line pressure to notify personnel as soon as loss of line pressure begins to occur or an increase of pressure. These simple pressure monitoring solutions feature a flashing light (optional audible alarm) that’s designed to grab the attention anytime pressure is rising too high or falling too low in a system. Preventing & fixing issues before they cause significant downtime!

Presair’s pressure alarm is available as field adjustable or factory set.

Built with a field adjustable pressure switch, this model can be set directly by the user with a range of 1-125 PSI. It can monitor pressure rise or fall at a the user’s set point using the stack light to notify light only or light & audible alarm.

Presair offers a factory set version with a smaller foot print than the adjustable pressure monitor. If the pressure in your system drops below or above your specified pressure, the stack light will notify using the light only or the light & audio.

- Multiple notification options available

- Variety of air connections available

- Pressure range of 0.25 inches of water to 125 PSIG

- Differential Pressure ±10 psi

- Protective switch housing options for tough environments

- The adjustable pressure switch is UL & CUL rated for 100,000 cycles at 5 Amps @ 240VAC.

- Stack light mounting options